🚀 Elevate Your 3D Printing Game with Alloy 910!

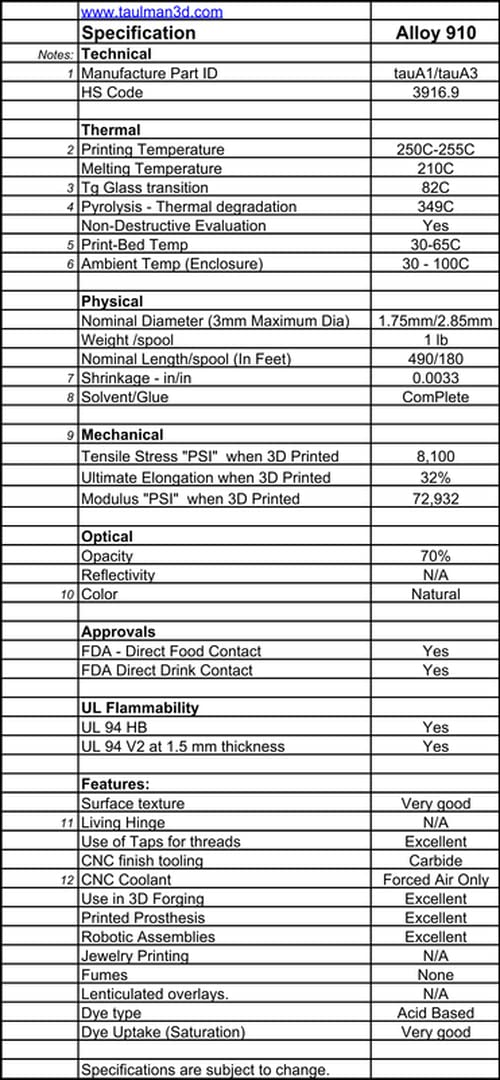

The Nylon Filament Alloy 910 is a high-performance 3D printing material, specifically designed for industrial applications. With a 1.75mm diameter and a generous 1kg spool, it allows for larger prints without frequent material changes. Compatible with most FDM printers, it extrudes at lower temperatures (250-255°C) and offers superior strength compared to traditional filaments like PLA and ABS. Manufactured in the USA, it guarantees quality and consistency, making it the go-to choice for professional designers and engineers.

| Manufacturer | Taulman |

| Brand | TAULMAN3D |

| Item Weight | 1 pounds |

| Package Dimensions | 8.7 x 8.39 x 3.23 inches |

| Item model number | Q99-PLA-3T |

| Is Discontinued By Manufacturer | No |

| Color | Black |

| Shape | Round |

| Material Type | Nylon |

| Number of Items | 1 |

| Manufacturer Part Number | Q99-PLA-3T |

G**M

Taulman 910 Nylon filament in Black...prints like PLA, feels more like ABS.

I've had this Taulman black filament for months now, and finally found a need to try it. This Taulman 910 nylon filament prints like PLA but requires far more heat at the extruder, around 250C-255C, with a bed temperature around 45C. It is also claimed by Taulman to be hard, like PLA. Previous experiences with Taulman nylon filaments were very favorable so I went with their suggestions. The results were excellent. With a layer of Elmers X-treme gluestick on the print-bed and everything heated to specifications, this printed very well on the first attempt, with absolutely zero warping. The gluestick holds it to the print-bed surface very well, even after the finished part had cooled, requiring some persuasion to remove the part from the print surface. Lesson learned! The claim to be as hard as PLA is probably a bit of an overstatement, but it's certainly harder and stiffer than other nylon filament I've used, and scraping a fingernail down a sharp edge caused no problem, at all. This is only a 1-pound spool and is considerably more expensive than most 2.2-pound spools of PLA and ABS from other vendors. That's about the only down-side of this product. Unfortunately, at this time there are only two color options, black and "natural". Except for the temperatures used, this was a 'plug-n-play' replacement for both PLA and ABS needs. It prints similar to PLA but feels more like ABS. For printed parts that need more heat resistance, such as around the hot-end heater block, this should offer better performance than ABS, which is usually used in those areas. This is also a high-strength filament, so this Taulman 910 filament should shine when more strength is needed.

T**S

Built for strength and printing ease

A nice balance between strength and durability, and ease of printing. A bit trickier to work with than petg, but not as difficult as most nylons or polycarbonates. Not much choice in colors but this filament wasn’t made for that, and while I have yet to try the white alloy 910, the black has a very nice gloss that in the right light can look bluish purple, by far one of my favorite filaments, if it wasn’t so expensive I would buy it more often.

A**E

Just will not adhere

Perhaps I got a bad roll, but after drying this roll in my filament dryer for 12 hours at 50°C, I tried a sample print of a paint pyramid. It failed to adhere to the bed, so I cleaned the glass, applied a thin layer of glue, pre-heated the bed and hot end, and purged the filament from the nozzle.With a clean nozzle in my all metal hot end, the bed heated to 70° I tried another print at 255°. This time the first layer went down, looked to be clean, so I let the print run for half an hour at 40mm/s. This time, the second layer would not adhere to the first, and I had a stringy warped mess.At this point, I decided that perhaps the issue was moisture despite the fact I had already dried the spool, I wanted to give it the best possible chance. So I put the spool in the dryer for another 24 hours at 50°c, then leaving the spool in the dryer, I went through the process, cleaned the bed again, preheated, purged filament from the hot end, and loaded up the Alloy 910 Nylon, hopeful that with the additional drying time, and the continuous use of the filament dryer, I would at last get a clean test.Sadly no, this time the print started off well, printed several layers successfully, so I stepped away and let it print for several hours thinking I had at last solved my issue. On returning, I again found a warped stringy mess, with the printer nozzle covered in Nylon.I shut the machine down, removed the cover, and found that at 255°c, the Nylon had clogged in the nozzle, backed up in the heater, and oozed out all over the heater block between the bowden tube, and created a tremendous hot gooey mess.So not only was I unable to get anything printed, but this has ruined the hot end because despite my best efforts, there was no way to clean it, and it was so bad, that it effectively welded the ceramic heater to the block such that I couldn't even remove it.I've never been so exasperated by a filament in my life. My only hope is that someone can explain what I could be doing wrong, possibly the manufacturer can reach out via Amazon with some tips or tricks.If I'm ever able to get this spool to work for me, I will update my review with details, but for now, I'm down to using the original hot end, so no Nylon until a new all metal unit arrives, and I'm confident I have a solution.Wish me luck!

A**E

Great Nylon Filament!

This is a great nylon filament. It took about 30 minutes to get it to print just right, just be patient. Obviously all printers and settings are little different, so what I print at may not necessarily work for you and vice versa. I’m using a Voxelab Aquila S2 (stock & no enclosure). I’m running the material at 250C with a bed temp of 55C, fan off and a print speed of 40mm. I use a dryer box that runs 24/7 and the print bed is a PEI sheet. No problems. I initially used the parameters for printing from the company’s website and tweaked settings in the slicer until it worked for me. Like I said, it took about 30 minutes to perfect the first print. I had about 4 failed prints up to that point but no more. Every print after the first printed flawlessly. I will definitely will be purchasing more of this material

K**E

This stuff is AMAZING. Sure

This stuff is AMAZING. Sure, you have to deal with a little bit of 'stringy-ness' - but nothing compared to other nylon. You of course need to prep carefully to get surface bonding. But, this stuff will print fantastically accurate prints, that have amazing strength. I used this to print my first FPV 250 drone and it has survived crashes that should have destroyed it and I am convinced would have destroyed my son's commercially purchased drone. Strong yet with a bit of flexibility and a good "memory" for printed parts to maintain their shape.

G**K

Garbage

I tried hot cold slow fast dry, super dry nope... Not good for a single thing.

L**E

Material sumamente increíble

Soy ingeniero y este material es fuera de serie... Con el diseño correcto y un buen análisis este material fácilmente se puede emplear en el sector industrial.

Trustpilot

5 days ago

2 weeks ago