Customer Services

Copyright © 2025 Desertcart Holdings Limited

⚡ Power your laundry with genuine Whirlpool precision!

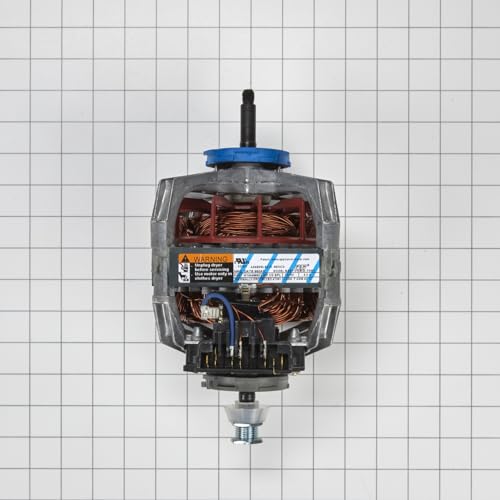

The Whirlpool 279827 Dryer Drive Motor is a genuine OEM replacement part featuring a robust 1 horsepower motor designed for Kenmore and Whirlpool dryers. It includes a reverse-threaded impeller fan for secure installation and is highly rated by users for reliability and value. This motor offers a cost-effective, professional-grade solution to restore dryer performance with easy DIY installation.

| ASIN | B00DM8JA5S |

| Batteries Included? | No |

| Batteries Required? | No |

| Best Sellers Rank | #373,626 in Tools & Home Improvement ( See Top 100 in Tools & Home Improvement ) #7,468 in Dryer Replacement Parts |

| Brand | Whirlpool |

| Brand Name | Whirlpool |

| Compatible Device | KENMORE |

| Customer Reviews | 4.6 4.6 out of 5 stars (1,599) |

| Date First Available | July 30, 2008 |

| Global Trade Identification Number | 00749853798275 |

| Horsepower | 1 |

| Is Discontinued By Manufacturer | No |

| Item Weight | 5 pounds |

| Item model number | 279827 |

| Manufacturer | Whirlpool |

| Material | ABS |

| Material Type | ABS |

| Model Info | 279827 |

| Model Name | 279827 |

| National Stock Number | 6105-01-024-8894 |

| Part Number | 279827 |

| Product Dimensions | 1.5 x 2.5 x 3.5 inches |

| UPC | 749853798275 883049372549 840383101051 |

| Voltage | 1 Volts |

T**Y

Great motor for the price with outstanding service

The good news is that this is a great replacement for the motor in our Kenmore dryer at half the price for of an American made motor. This motor is made in China and the frame is less rugged than the American version. It also is slightly louder but well within the acceptable range especially if you have a door on your laundry room. (We always keep our door closed anyway.) The bad news is that the first motor I received made such a loud noise that my wife thought it was the buzzer that sounds when your close are dry. When I reported this to the seller they sent me an RMA along with a UPS mailing label that did not include home pickup but the local UPS office was nearby so not big deal. Installing the motor requires that the dryer drum be removed and that the impeller fan be removed from the motor shaft. Taking the impeller off the shaft presented a little problem because it is not obvious how it is attached. I waited until the new motor arrived and found that the impeller is screwed onto the shaft in such a direction that it tends to tighten as the motor turns. If you are at the back of the dryer you can unscrew the impeller by turning it clockwise. The other end of the shaft can be held by placing a wrench on the hexagonal shaped wheel to which the drive belt attaches. I first tried to remove the impeller by using a wrench on the square end of the impeller that attaches to the shaft. I do not recommend this method as it could damage the impeller which is exactly what I did but I realized my mistake soon enough to prevent serious damage. I finally was able to remove the impeller by immobilizing the impeller and by turning the shaft (hex end) clockwise (as seen from that end of the motor). When you install the new motor, make sure you align the little protrusion on the plastic collar with the notch in the motor bracket. I used a large screwdriver and a hammer to put the spring brackets brackets back on. I lined up the bracket, put the screwdriver in the curved end of the spring bracket and gave is a sharp tap with the hammer and it popped right in to place. Reinstalling the drive belt can be a little tricky if you didn't notice how it was installed before you took it apart. I suggest you use a digital camera before you disassemble it and take a picture if you don't think you will remember how it was connected. If you already removed it and didn't take a picture you can find parts diagrams on-line that illustrate how it should be connected. You may need a helper to hold up the drum while you put the drive belt back on the motor. Finally I think I could have avoided replacing the whole motor if I could have found a replacement capacitor. I'm going to hang onto the old motor and keep looking for a new capacitor. If I find one I'll fix the motor and keep it for future use or sell it on-line. Revised Update: I previously reported that this motor failed after 18 months. I was wrong, the motor did not fail. Read on and you'll be shaking your head by the end. I originally reported the "failed" motor to the vendor who kindly sent me a replacement even though it was out of warranty. When I installed the replacement it also did not work. Voltages were fine but the original motor only turned slowly while the replacement only buzzed. I contacted the vendor who now was a little suspicious. Nonetheless he asked me to send the two "bad" motors back for testing. If he finds they are both faulty he will reimburse my shipping costs and send me a new motor. Fine, I did as he asked. We had already been without a dryer for over a week and I realized that it would probably be two weeks before we would get a replacement motor. I decided to buy a used dryer that we could use in the interim. When I picked up the used dryer it was running so I knew it was working but when I got it home and plugged it in, it didn't work. It only made a little hum. I knew I was in trouble and decided that there must be something wrong with the electric even though the voltages on both hot wires of the 220 volt line were fine. I thought it might be a bad circuit breaker so I shut off the power and took the breaker out. It seemed fine, no signs of arcing, no corrosion, no bad smell, it was fine. I stepped back and took a look around the rest of the circuit box and discovered a wire at the bottom that had melted in two. Further investigation showed that the wire had connected the ground bus to the common bus something that is not uncommon in older homes. When I removed the wire I was dumfounded by what I found. It wasn't a wire at all. It was a section of coat hanger!!!! It still had the little curly part that is left when you untwist a hanger. I have no idea who the idiot was who did this but he could have burned the whole house down. We bought this house in 1985 so it has been that way for a long time. This still did not explain why the motor didn't work but I soon discovered that the common line from the dryer circuit had been connected to the ground bus and not to the common bus as it should have been. I moved it over. I turned the power on and when I tested the dryer it worked. There was some corrosion on the aluminum ground-bus. Although aluminum is a good conductor, aluminum oxide is not. As the ground bus corroded it became less and less conductive and more and more of the electricity was flowing over to the common bus through the "coat hanger wire" which also was corroding. Finally as the current increased it got so hot that it melted and the dryer failed because the electricity could no longer flow through the circuit. I will soon be replacing the whole electric box but just to make sure there is a good ground until I install the new circuit box, I connected the ground and common buses together using a heavy gauge copper wire. Today I received my original motor back from the vender and installed it in the dryer. It works great and I was not charged for the return shipping. I had previously downgraded my first rating from 4 stars to 3 stars. I am now changing it to 5 stars. The motor works great. It may be slightly louder than the original but the service I received from Seneca River Trading, Inc. was outstanding. They had good reason to suspect that I was trying to get a free motor but they never accused me of that and they continued to work with me until my problem was solved. They spent a lot of time and even paid for the return shipping. Now that is outstanding service and I will never ever hesitate to order from that company in the future. I highly recommend this motor and Seneca River Trading, Inc.

U**.

279827 Dryer Motor

Dryer motor 279827. From PARTSHOUSE. Mexican made FSP-Whirlpool part, works great. NOT a cheap Chinese copy. This is a new part, not rebuilt. Ordered Feb. 2013 through Amazon 8pm Friday night on long weekend, therefore no Monday mail. Arrived in Boston Wed. AM using standard shipping (USMail). Shipped from PARTSHOUSE in PA. Also bought belt 341241 which appears generic even though photo shows an FSP-Whirlpool packaging. Saved old belt for a spare, just in case. This motor is so quiet I can now hear the air going up and out the exhaust. The old motor must have been junk for a very long time. Eventually it started overheating and shutting down, and would make a buzzing sound at start-up. Motor bearings were squeaking too. While I had it apart, changed the drum rear rollers, cleaned it all up, and scraped every bit of the noise-generating caked-on gunk out of the rear roller track on the drum, and I am waiting for front and rear drum seals and front drum glides from another vendor, who is not as quick as Amazon's Partshouse. New appliances seem to have a very high failure rate and a short lifespan, so for less than $150 I changed out the guts on this old Whirlpool and it's better than new. There are online appliance repair clinic videos on other sites which also sell parts. If you're a little bit handy, these appliances are fairly easy to fix. When ordering this motor, be sure the bearing color is the same as your old motor (blue or orange). The part numbers are similar for similar-looking motors, so be careful. Also, the fan has REVERSE THREADS on the motor shaft, so "right is loose, left is tight" in this application, instead of normal left-is-loose-right-is-tight. I hope this helps someone get their stuff going again.

W**T

Worked on this 25-year-old dryer.

H**H

This motor worked well so far. Amazon.ca was cheaper than local part stores' prices and the delivery was quick (the amazon.ca price has gone up). It is important that you know what you are getting into: watch online videos about dryer repairs. Make sure that you are getting the right part. Diagnosis is sometimes tricky. I first tried one of these but it didn't solve the problems https://www.amazon.ca/Factory-Original-Whirlpool-4392065-Rollers/dp/B00DQCK0EU/ The motor is connected to a blower wheel. Ours was impossible to separate without destroying it so we needed a new blower wheel too. If you check before you order, you could order both at once which would cut down waiting time. I'm impressed that parts were still available for a 30+ year old dryer. I had to do a bit of wire stripping and connector crimping since the connections have changed (but the bits were included and so were the terse instructions). With an old dryer, consider replacing the whole thing.

L**E

Exact fit, great price, whoo hoo the kenmore dryer is running like it was brand new!

L**Y

Easy to install. Works perfectly. The price was quite good.

P**N

Perfect fit. Needed small rewire as per instructions include

Trustpilot

1 month ago

1 month ago