Customer Services

Copyright © 2025 Desertcart Holdings Limited

⚙️ Elevate your DIY CNC game with power, precision, and pro-level versatility!

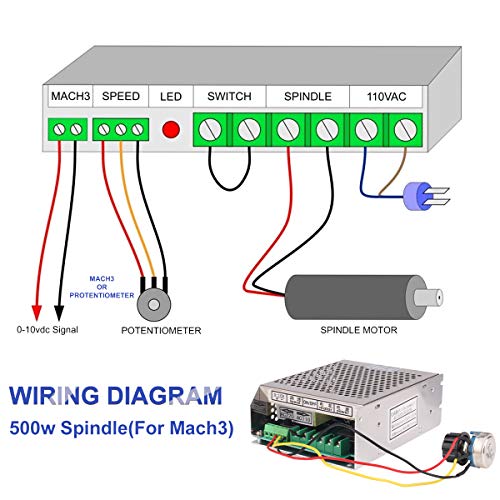

The MYSWEETY 500W CNC Spindle kit features a high-torque, air-cooled 0.5kW motor capable of speeds up to 12,000 RPM. It includes a 52mm durable aluminum mount bracket, a 13-piece ER11 collet set for tool versatility, and a speed power converter compatible with AC110V/220V inputs and MACH3 control software. Designed for quiet, precise milling and engraving on materials like wood, plastic, and acrylic, this spindle is ideal for professional-grade DIY CNC projects.

| ASIN | B01LNBOCDA |

| Best Sellers Rank | #364,291 in Tools & Home Improvement ( See Top 100 in Tools & Home Improvement ) #70 in Power Milling Machines |

| Brand | MYSWEETY |

| Date First Available | September 6, 2016 |

| Horsepower | 0.5 Kilowatts |

| Is Discontinued By Manufacturer | No |

| Item Weight | 4.71 pounds |

| Item model number | 500W |

| Manufacturer | Mysweety |

| Material | ABS |

| Product Dimensions | 2.2"W x 7.83"H |

| Speed | 12000 RPM |

| UPC | 713839365553 |

| Voltage | 220 Volts |

A**R

Excellent quality at a good price

I ordered this to replace a smaller 300 W spindle on my 3040 CNC router. The reason i picked this one is, it has the same diameter and fits the same holder. Some 3040’s require a little bit bigger operation to swap out the spindle for a bigger motor than this. I changed all my wiring and connected the new motor. First I thought the spindle wasn’t running, but then I noticed my speed pot was in the bottom third of its range, at about 30%. This spindle runs so quietly, I just didn’t hear it. After you turn it up past 50%, you can hear it running. I would say it’s at most 30% of the noise of the original drive. It’s running very quietly, no noticeable run out, plenty of torque. Actually it has about 66% more torque than my old 300 W spindle. I have not cut much with it yet, but I am still extremely happy. I wish I would have started with this drive. One comment I would have for people wanting to use this as a mill. We run other bigger machines as well. To me a mill is probably mostly used to machine aluminum and other metals. That requires lower rpms and more torque. That’s not what these smaller routers and spindles are designed for. These smaller machines and spindles are for routers and engravers. That requires higher rpms and normally less torque. This spindle works perfectly for that purpose, and it can perform these functions at a great speed and accuracy. As one can see in the attached pictures, I used this to route 3/4 in maple for my backlit acrylic picture holders, I run 1/2 plastic, HDPE, 1/4in acrylic, and I use it to engrave my backlit acrylic pictures. So, clearly it does all these jobs, and I think it does a great job. But you need to pick the right speeds and bits for the job. I would definitely recommend this spindle and I am very happy with my purchase.

B**.

Really nice for small CNC machine

I had an old 3d printer that was 300x300x400mm format. I took this spindle motor and combined it with the cnctopbaos 3 axis grbl controller. The controller works great but it has absolutely no documentation with it so you will need to be at least intermediate level with electronics or I wouldn't recommend going this route. The controller board has a spindle motor output from 0 to 24volts and this motor controller needs a 0 to 10volt signal to control speed. I created a cheap voltage divider and then connected this signal up to the pins that are shown with the potentiometer, now the software controls all 3 axis and the speed of the motor. Be careful using this with a cheap control board, on most of them you cannot drive this motor directly, it draws too much power and could burn up the control board. If you use this motor control and find a way to get a 0 to 10 volt signal out of your controller you won't have any problem.

A**R

Very good purchase

I have to admit, this motor is much quieter than I expected for a brush contact. More important, the torque and speed are as advertised. Very smooth operation and high precision, with almost no run-out. No idea how frequently the brushes will need replacing; but I do imagine relatively low maintenance due to balancing. Pros: Everything mentioned above. Very smooth and quiet operation with tight tolerances. I really like the design of the fan. It is mechanically connected to the shaft instead of electrically driven, so it does not leech from the power supply. The shroud is also properly sized such that it blows down and around the motor chassis, cooling the entire body. The shaft is milled from a good grade steel. With a 6mm bit in the collet, the shaft extends about 45mm from the housing to the end of the nut. So far, the shaft has proven to be rigid enough to support that reach without deflection. Cons: All of my cons are related to the power supply. No complaints about the motor. The power supply case does not easily support a variety of installation/mounting options. 2 holes on the horizontal plane (one is open), and 2 holes on one wall. Complete disassembly is required in order to drill new mounting holes. Additionally, the main board does not provide ample clearance for mounting screws to fit underneath without contacting the board. Only one of the transistors had thermal paste applied. The other was dry. Both are pressed against a plastic card, insulated from the chassis. Recommend disassembly upon unpacking, in order to check and apply more thermal paste. Further recommendation following my next con... The chassis is not grounded. This is why the transistors are insulated from the chassis--to prevent electrical noise in the output. Recommend installing a power cord with ground, and connecting the ground to the chassis. Then the plastic card can be removed from the transistors, allowing them to contact the chassis and dissipate heat more effectively. The chassis ground will also provide better EMF shielding so that the power supply does not induce interference into nearby controllers/electronics. Chassis ground will also provide better protection against line voltage surges. The labels for the terminal board are almost entirely in Chinese. No instruction pamphlet is provided. The only English language wiring guide available is in the photos in this Amazon listing. DOWNLOAD THOSE PHOTOS. When this product is unlisted, those photos will likely be no longer available. The on/off terminal connections are hard-wired together out-of-the-box. No switch is provided. Without modification, the power supply is immediately powered up upon connection to line voltage. *Make sure the potentiometer is turned completely off (counterclockwise) before plugging in. The line power terminal connections are not separated from the motor output connections. Care must be taken to ensure no wire strands are loose and at risk of short circuit. This power supply would never pass US UL inspection. Again: Strongly recommend modifications for chassis ground. I installed the power supply into a plastic project box in order to protect the exposed terminals and board from debris and external contact. Using a slightly oversized box, I also installed the potentiometer and a power switch into the box for better component space management.

I**N

dead on arrival

Did not work. First I had to google translate the instructions because it did not come with any. When I finally got it working, It was severely underpowered. Worse than my original 75W spindle. Guess I have to take it all apart and start over.

T**N

Great CNC spindle (for wood)

It was perfect for my CNC build. It's small size and light weight made it easy to mount on my home-made CNC. Even a set of collets were included. It works great for slow speed CNC milling in wood. For metal or production work it's just not beefy enough for that. It bogs down when working with aluminum unless you go really slowly. I did use it to drill pilot holes in an aluminum plate though. It took a long time and required WD-40 but the pilot holes made for perfect location drilling at the drill press afterwards without needing to measure or make jigs. I needed a low RPM for the CNC drilling which this unit allows me to do by adjusting the speed down with the provided speed control knob. (as slow as it can go without stalling) You want to use about 500 RPM for aluminum drilling, not 13,000 RPM to 35,000 RPM like the typical milling routers have! I would say that this spindle is mainly for working with wood and low power projects and it does a nice job at that. I'm pleased with the quality of it.

I**.

Entrega a tiempo, calidad de acuerdo a lo ofrecido, resumiendo, muy buen producto

S**S

Je l'ai monter sur ma CNC elle fonctionne très bien Bien emballé envoyé rapidement très satisfait Il manque un petit schéma pour le câblage surtout pour la polarité de la broche j'ai fait avec le schéma que on a sur amazon

B**D

Guter Preis , schnelle Liederung

A**R

Runs silky smooth and silently up to about 1/2 speed. After that there is just the wind noise from the fan, and not even a lot of noise from that. Runout could not be measured from my dial gauge but looked to be less than 0.0002” (Yes, that is the correct number of zeroes.) Hookup was easy. Mine came with the switch set to the 220 volt position so check this before applying power. Unit came with a speed pot which was not included in the advertised material list so that was a bonus. One caution if you are testing the unit before installation, the fan on top of the motor is not enclosed in the plastic cap, rather the whole cap spins. If you have the motor lying on the bench, the fan will act like a wheel and move the motor. The power supply mounts with #6 screws. This appears to be a great little unit.

E**L

dopo che ne ho cambiati 3 finalmente questo funzionava silenzioso rispetto all'originale ed un ottima potenza

Trustpilot

3 weeks ago

2 weeks ago