Customer Services

Copyright © 2025 Desertcart Holdings Limited

🔥 Weld Like a Pro, Every Time! ⚙️

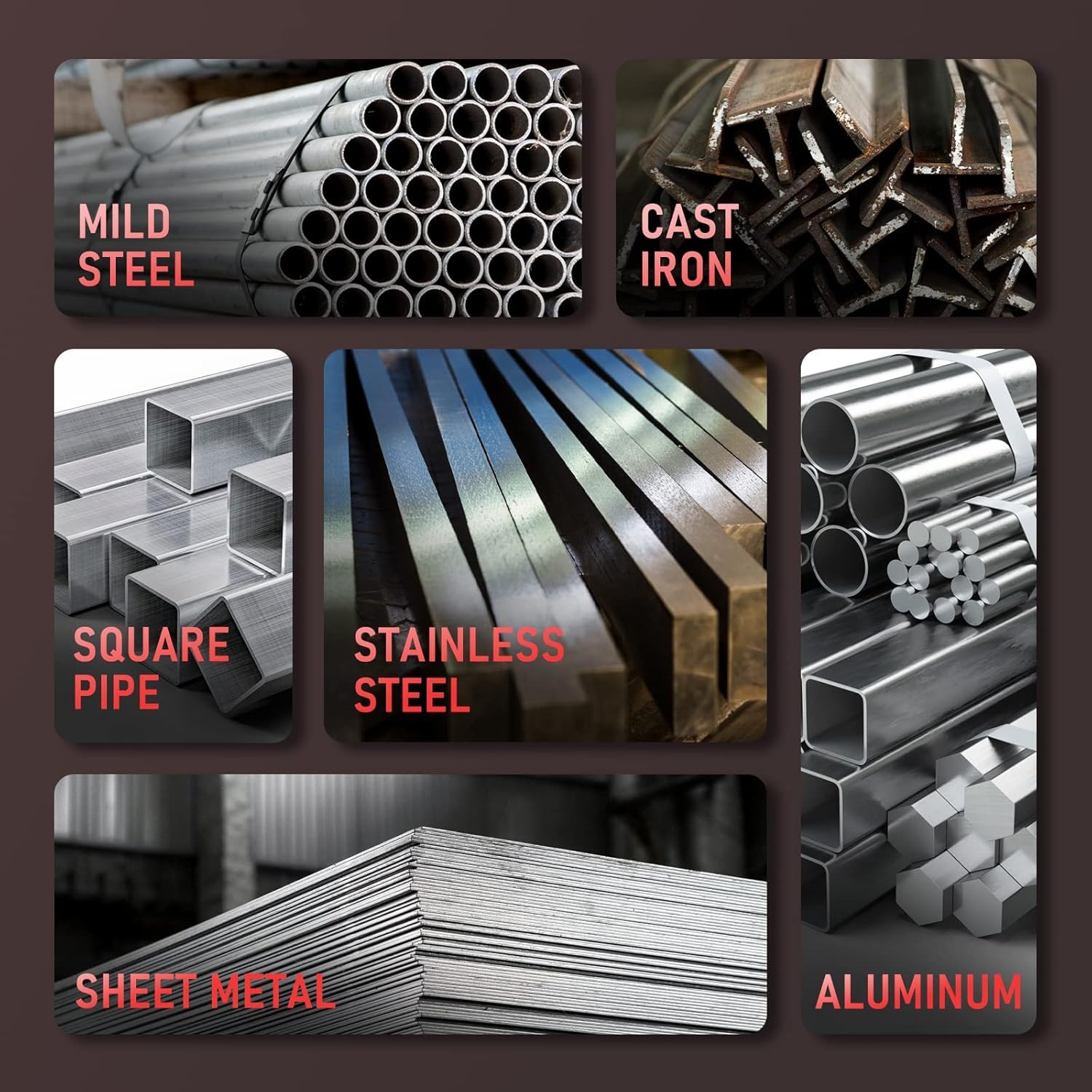

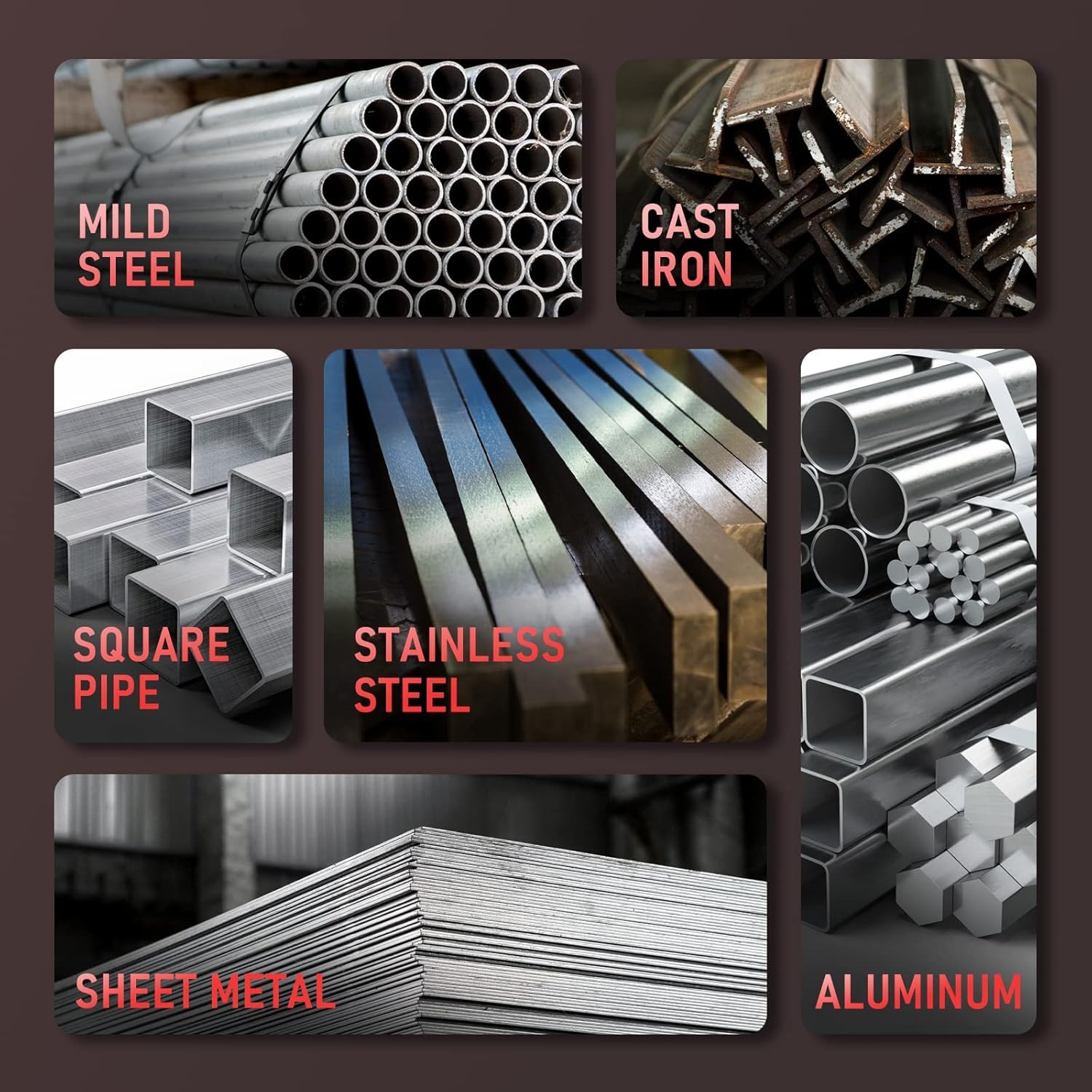

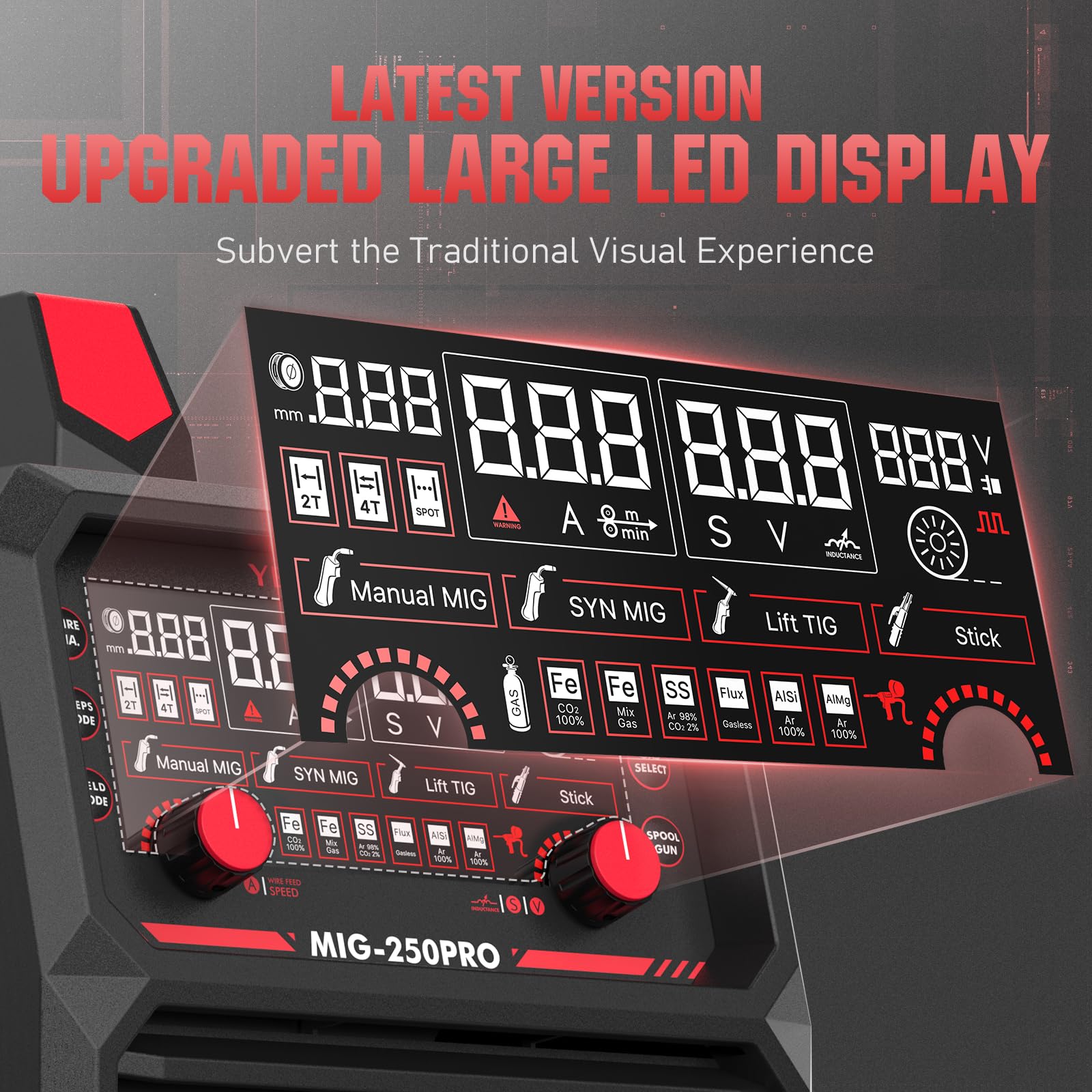

The YESWELDER MIG-250PRO is a versatile 6-in-1 multiprocess welding machine delivering up to 250 amps with dual voltage (110V/220V) compatibility. Featuring advanced digital controls, synergic MIG technology, and comprehensive safety protections, it’s engineered for professionals and DIY enthusiasts seeking precision, power, and reliability across MIG, TIG, Stick, and more welding applications.

| ASIN | B08CBCB4M5 |

| ASIN | B08CBCB4M5 |

| Batteries Included? | No |

| Batteries Required? | No |

| Customer Reviews | 4.4 4.4 out of 5 stars (548) |

| Customer reviews | 4.4 4.4 out of 5 stars (548) |

| Date First Available | 5 May 2021 |

| Date First Available | 5 May 2021 |

| Item Package Quantity | 1 |

| Item Weight | 17 Kilograms |

| Item model number | MIG-250 PRO |

| Item model number | MIG-250 PRO |

| Manufacturer | YESWELDER |

| Manufacturer | YESWELDER |

| Material | Metal |

| Package Dimensions | 54.61 x 40.64 x 35.56 cm; 17.01 kg |

| Package Dimensions | 54.61 x 40.64 x 35.56 cm; 17.01 kg |

| Part number | MIG-250PRO-AL |

| Size | MIG-250PRO |

| Style | MIG-250PRO |

| Voltage | 220 Volts |

M**T

Seems like a great, affordable welder to replace my Millermatic 211. I've not been happy with my 211 ever since it was new ($2500 CAD!). In automatic mode the 211 just struggled to operate smoothly compared to an older one it replaced, so I've been looking for a replacement for a long time. After seeing several reviews of the Yeswelder mig-250 pro by real, professional welders, I decided to get one at a fraction of the cost of the Millermatic 211, and capable of way more, and at a higher duty cycle. So far I'm quite impressed. I will only be using MIG in synergic mode, and it works very well. I set the wire feed speed according to the chart to stat with and let it run the voltage itself. On very thin metal it's way better than the 211. With thin steel and contaminants, the 211 would often spit and hesitate, leading to some very ugly blobs. No such problem on the MIG-250 Pro. Can fill holes and gaps, penetrates well without burning through too badly. Occasionally the wire will vaporize in a flash while starting, but that was the only issue I found on the thin stuff. Welded through paint and dirt much better than the 211. On heavier steel it worked well. I ran it up to maximum wirespeed on 3/8" steel bar and it laid a very nice bead that seemed to penetrate well. This is all with synergic mode which works well for me. I did briefly try stick welding with it and it had no issues but I'm no stick welder. Some time I plan to adapt my Miller 300 spoolgun to work with this welder and give pulse mig a try on aluminum. I've only found a few things I don't like about the welder. Loading the wire and feeding it into the wire feeder is very awkward, due to where the feeder is positioned. The spring tensioner on the spool axle wasn't on very tight and the manual says nothing about tightening it, but it definitely needs to be set right to get the proper tension on the wire and prevent the spool from unwinding when you stop welding. The grounding clamp is rubbish. Plan to buy a good clamp and throw this one away. Finally I didn't really like the stick welding hand piece. It has pretty good strength to grip the rod, but the shape and width of the clamping surface isn't ideal in my opinion. If you plan to do much stick welding, consider replacing it with a good stinger, perhaps one of those ones you twist to tighten up on the welding rod. Despite that giving it 5 stars because it's a fantastic welder at an unbelievable price. If after a year or two I start seeing problems with quality I'll adjust my review.

E**C

I’ve been putting together a metal building with this welder. Started off welding these columns I had. Half inch thick to half inch thick base plates. Put a bevel on them cranked Welder up to 26 1/2 V. Using flex core because I’m outside in a windy condition didn’t have any problems. Have been using it for about three months now ran about 25 pounds of wire through it. All of a sudden the wire feed quit. Went through all the troubleshooting no help. I called customer service. They gave me some other ideas. Still no wire feed. They asked for some videos which I sent. They determined something faulty went wrong and said they were gonna send me a new one. Keep the old one. Took about three or four days to get the situation handled. I’m gonna take the old one apart when I get a chance and see if I can figure out what happened to the wire feed. I mean, it just quit in the middle of a weld. If I can’t fix it at least I got extra parts for the new welder or if I can’t fix it I got an extra back up Welder. I’ll give an update on the original Welder when I get a chance. Other than that, the welder worked great I’ve been just using it in the manual mode because the automatic setting mode runs a little bit hot. I wouldn’t call myself a professional welder, but for the last 50 years, I have built numerous projects with stick and mig welders. Mainly using Lincoln products. This Welder was really easy to set up. The only bad thing I could say is the welding clamp was one of them cheap ones, but they all come with the same thing. I bought a heavy duty brass one. Also the power cord it comes out of is only a 12 gauge cord. I’m running a 50 amp breaker with 6 AWG SOOW extension cord that I got from prime weld which by the way is a hell of an extension cord. Anyway, the cord comes out of the welder gets a little bit warm if I’m welding a lot of really thick stuff. I got an 8 awg cord that I’m going to a fit to the new Welder. I hope it doesn’t void the warranty. Other than that, this Welder does everything that I have asked for. At the time I bought it it had $120 discount coupon with it so I only paid about $450. I also bought their plasma cutter 65. When I took it out of the box, I tested it on a piece of scrap three three-quarter inch steel. It was a messy cut, but it cut it. Cutting half inch is pretty clean. It easily cuts 3/8 pretty fast. Now I was using a 220 the whole time. I had to go cut some steel for a friend one day and we only had a 110 generator so I will say using the 110 does work but on using the 220 it works a lot better. But back to the 250 Pro I really like this Welder and if I had to buy another one, I would. Especially since the warranty and customer service was so great. I mean for the price I paid if I weld with it every day with this thing and burned it up within a year warranty I guess they would’ve just sent me another one. So if you’re just hobby Welder or a small shop, Welder, I would definitely recommend this Welder. I mean if you go buy a Miller, you’re gonna spend 2000+ dollars.

G**G

Overall very happy with the welder. Lays down a good bead and was easy to set up. Instruction manual could have used some work but lots of info online to help get it set up. Yes even has a video on set up that helped the most. I initially had the postive/minus reversed and was welding caterpillars. The settings decal they give is very hot. I immediately got concerned it was an overrated welder when i saw 250 amps and max the welder out for 1/4"(which is what I weld most of). I tried it and the plate was glowing when I got done. I looked at the Miller App(its great btw) and realized it had voltages/amps/wire speed. I initially missed it had voltages. I then adjusted down to that and didn't get quite good penetration. I upped it about 1/2 volt from Miller and sped up the wire a tick(that was easy, could tell it didn't sound right) and it is welding great. Someone else on Facebook said the miller app is money for the 250 Pro. For mine it isn't...so I'm guessing the low cost components vary from welder to welder a bit. Just have to adjust but a good starting point on mine is the top end of what miller says. It appears you could likely weld 3/8 w/o much issue with this. I don't know if the 250 Pro is 'overrated' like their older 250 versions that I've seen several bad reviews on(claim only capable of 180 amps barely)...but it welds 1/4 like a pro(I'm an amateur) and I can't complain. I have work to do but am laying pretty nice beads right now. Just have to hone in my process. I'd say this works great for heavy stuff. Haven't done much thin stuff. Cons of this welder that I saw online before it even arrived. Yes should just upgrade the clamp to a forged or whatever Hobart style. Saw them for 15 bucks at Harbor Freight. I cut the cheap ground clamp off mine and put the new Hobart one on and its great...I don' tknow what a cheap clamp does but for 20 bucks after I put it on the welder seemed to wake up. I also saw someone complain the gas hose fittings were not standard. I threaded the one that came with it right in to my Victor regulator I bought at LInde Gas...and it worked great.(Still deciding if there's a small leak...just got a new cylinder so I"ll be making sure its air tight). If you're on the fence...I'd be hard pressed to believe you can get a better welder for the money. I haven't tried Tig or Stick. I could see trying Tig but doubt I ever do anything with the stick. Grumpy that this thing went on sale a week after I ordered it for 25 bucks less. I did order the 4 yr replacement plan on it from Amazon just to be safe. I'll use it for projects like Rock Sliders and such for off roading. A couple projects a year likely.

W**H

Alright so this is gonna be a very honest reveiw, i am a welder, i do this for a living, i bought the mct-520 from YESWELDER, it didnt have enough power to push .030 e71t wire without stuttering, it just couldnt do it efficiently, i do stick, fluxcore, and tig both at work and home. Now i sent my mct-520 back and got this one because of the higher amperage duty cycle, figured maybe it could handle it better, i have a stick and tig welder at work but wanted a flux core for pipe repair and thin stuff thats extremely dirty, i used the same wire, the same mb24kd mig gun on both, and this one ran amazing, its super smooth, very powerful, better than the esab rogue i have at work, which is saying something, i use it for all 3 processes, now for the fluxcore im running hobart e71t-11 .030" wire, and this thing hasnt bird nested on me even once, its smooth, its consistent, i used it just yesterday welding rails on a mezenine for about 8 hours worth of welding, i also built a 3 ton hoist with this thing and it was good. I run mine on 220, i dont use 110 even at home, i have a 220 outlet i hooked up for it, itll run stick like a champ too, i mean honestly i can run a 1/8" 7016 rod as low as 70 amps, i ran some 5/32" e308l16 rods the other day bridging a 2 inch wide hole in a machine plate at around 70 amps and it did it very well. So i am extremely pleased with the output quality of this machine, and the build quality is very nice too, the only thing i dont like is the euro style connector for the mig gun, its not bad, but its not nearly as durable as the tweco style american mig connectors, so it can bend easily if hit, but besides that, the machine itself is really well built, i work in a concrete plant for quickrete by the way im a fabricator, so this thing is used in an extremely dusty dirty harsh environment and its holding up well.

A**S

Great welder!!! Have had it over a year now and it does everything as advertised. However the trigger switch has had to be taken apart and cleaned a couple of times which is kind of hard to do. It is a pretty cheap switch. But other than that it welds really nice and the duty cycle has been more than what I need and it is 100% duty cycle at 193 amps which can do most of the welding I need. all in all it is a great welder and has never let me down

Trustpilot

2 weeks ago

3 days ago